Alright, so check it, today I’m diving into something I’ve been tinkering with in my garage: bore vs stroke in engine design. It’s not just textbook stuff; I got my hands dirty actually measuring and comparing things, so let’s get into it.

First off, I started by grabbing a couple of different engines I had lying around. An old Honda motorcycle engine (single cylinder, small displacement) and a lawnmower engine (also single cylinder, but slightly bigger). My goal? To physically measure their bore and stroke and then try to understand how that affected their performance. I wasn’t just reading numbers; I wanted to feel the difference.

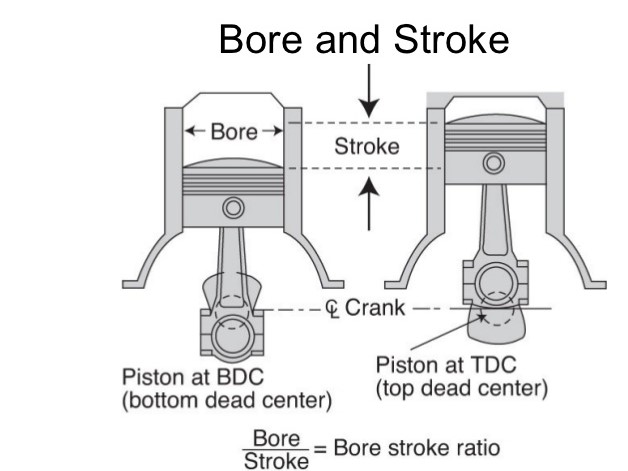

The measuring process was pretty straightforward. Took the cylinder heads off (after draining the oil, of course!). Then, using my trusty calipers, I carefully measured the inside diameter of the cylinder. That’s your bore. Getting a precise measurement took a couple of tries; you gotta make sure you’re perfectly perpendicular to the cylinder walls. Write that down. Then I used a dial indicator to measure the stroke. You basically set it up so it reads the piston’s travel from its highest point (top dead center, or TDC) to its lowest point (bottom dead center, or BDC). Finding TDC and BDC accurately is key here, or your stroke measurement will be off.

Numbers in hand, the fun began. The Honda engine had a smaller bore and a longer stroke compared to the lawnmower engine. This got me thinking about the characteristics each design brings to the table. Shorter stroke, bigger bore (oversquare) tends to rev higher and produce more horsepower at higher RPMs. Longer stroke, smaller bore (undersquare) usually means more torque at lower RPMs. I wanted to see this in action.

Next step, I decided to test this theory, although somewhat unscientifically. I couldn’t exactly strap these engines to a dyno. But I did try to compare their “feel”. I started the Honda engine. As expected, it felt zippy and eager to rev, it made me want to push the revs higher. The lawnmower engine, on the other hand, felt…well, torquey. Even at lower RPMs, you could feel it wanting to pull hard.

The real kicker? It wasn’t just about bore and stroke numbers on paper. It’s how these numbers translate to real-world performance. I mean, the Honda engine felt lighter and more responsive, perfect for a motorcycle where you’re constantly changing gears. The lawnmower engine, with its low-end grunt, was ideal for, well, cutting grass!

Lessons learned? Bore and stroke are crucial factors in shaping an engine’s character. Oversquare engines love high revs and horsepower. Undersquare engines thrive on low-end torque. There were some takeaways like it really helped to see and feel this physically. Getting your hands dirty like this is way better than just reading about it.

- Measure Carefully: Precision is key when measuring bore and stroke.

- Consider the Application: The ideal bore/stroke ratio depends on what you’re using the engine for.

- Get Hands-On: Nothing beats physically comparing engines to understand the differences.

That’s it for today. Next time, I’m thinking about diving into compression ratios and how they affect performance. Stay tuned!