So today I was under my neighbor’s pickup truck helping him check some weird clunking noise when I noticed these layered metal strips holding up the rear axle. Looked like a stack of ruler blades bolted together, y’know? Made me realize I actually had zero clue how these leaf spring things really function. Figured it was time to fix that.

My Total Noob Approach

First I googled “how leaf springs work” and got bombarded with engineering terms that might as well be Klingon. Ugh. Shut the laptop halfway through. Decided to go analog instead.

Grabbed a plastic ruler off my desk – the flimsy kind. Held it flat between both hands and pushed the ends downward. Bent into a nice curve, real smooth. That’s basically one big leaf doing its job, I guess. But then I noticed something: it bounced back way too quick and vibrated like crazy after bending.

Crumpled a stack of printer paper to roughly the same width as the ruler. Piled like seven sheets together unevenly and taped ’em real messy at the ends. Tried bending that whole wobbly stack. Complete disaster – papers slid sideways and flopped everywhere. Got it all wrong.

The Lightbulb Moment

Took a deep breath. Untaped the mess and restacked the sheets neatly this time, aligning edges properly before taping. Replicated the bend test. Boom! Resistance felt different – thicker and less shaky. The stack held its curve longer and the vibration dampened significantly. Felt sturdier even with just paper!

Started testing different combos:

- Three thick pieces of cardboard? Barely bent but rock solid.

- Ten receipt paper strips? Sagged like wet noodles immediately.

- Five index cards? Perfect middle ground – curved nicely while staying in shape.

Finally Seeing the Leaf

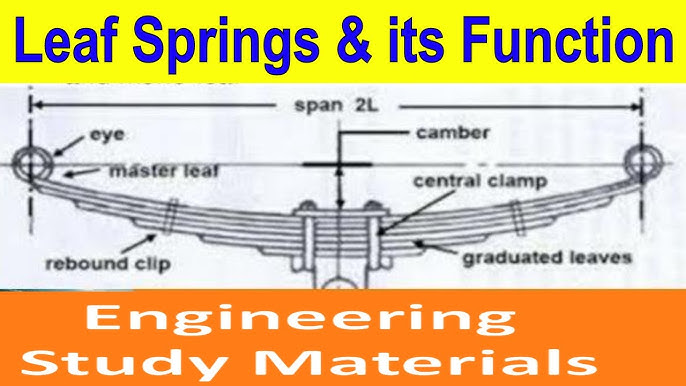

Visual clicked. That single ruler acting like one big master leaf handles the main curve. Adding shorter, well-stacked layers underneath does three key jobs:

- Makes the whole thing stiffer without cracking.

- Stops excessive bouncing by absorbing shake internally between layers.

- Takes pressure off the main leaf so it lasts way longer.

Remembered the truck and everything made sense. Those multiple steel strips clamp together like my successful paper stack to carry heavy loads while smoothing out bumps. Test proves it – no fancy math needed.

Dropped the ruler, washed the paper dust off my hands, and grinned. Sometimes the simplest tools get you the answers.