Alright, let’s talk about this Kawasaki KX 250 engine I’ve been messing with. It’s been sitting in the corner of my garage for a while, came out of a bike I picked up cheap that was pretty clapped out. Decided it was finally time to dig into it.

First things first, got it up on the bench. Always feels better having it at a decent height instead of crawling on the floor. Started pulling things apart. Off came the pipe, then the carb. Drained the old oil, nasty stuff. Then I started on the engine covers. Clutch side, ignition side. Had to give a few bolts some extra muscle, seemed like they hadn’t been touched in years. Found a bit of metal fuzz on the magnetic drain plug, not great, but not the end of the world either.

Getting Inside

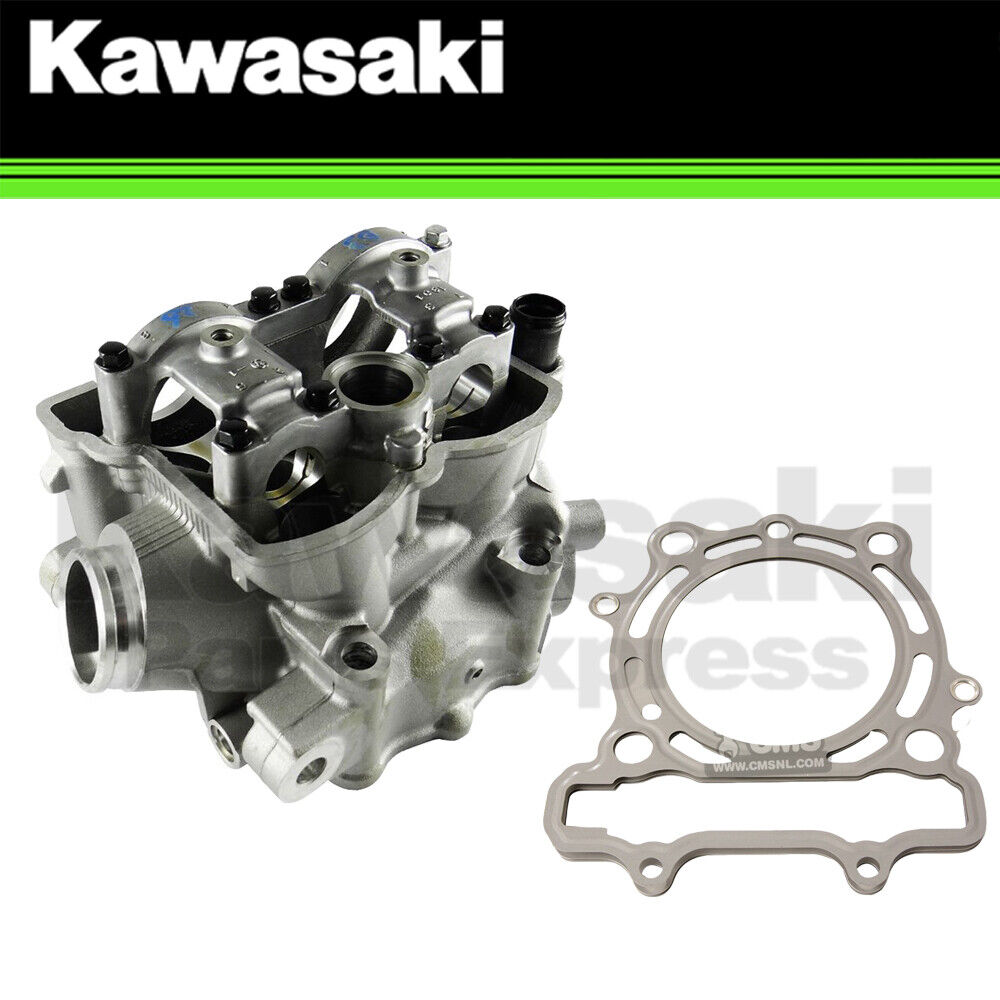

Pulled the head and cylinder next. That’s where you really see what’s going on. The piston looked pretty tired. Skirts had some scoring, nothing too deep, but definitely showing its age. Rings were probably shot too. The cylinder wall actually looked okay, surprisingly. Just needed a good hone, no major gouges.

So, the plan became a top-end rebuild. Ordered up a new piston kit – piston, rings, wrist pin, clips – and a full gasket set. You always need more gaskets than you think.

- Pulled the old piston off the connecting rod.

- Cleaned the carbon off the power valves, what a messy job that is.

- Cleaned the cylinder surface, got it ready for a light hone.

- Scrubbed down the engine cases while I was waiting for parts.

Waiting for parts is always the worst part. Had everything laid out, cleaned, ready to go back together, just twiddling my thumbs for a few days.

Putting it Back Together

Finally, the parts showed up. Got the new rings onto the new piston, making sure the gaps were right. Oiled everything up real good. Getting those wrist pin clips in without launching one across the garage is always a fun little challenge, right? Managed it this time without losing one.

Slid the freshly honed cylinder carefully over the new piston and rings. Used a ring compressor, makes life way easier. Bolted down the cylinder, then the head, using the torque wrench. Gotta follow the sequence, tighten them down in stages. Don’t want any leaks.

Then it was just a matter of putting everything else back on. Clutch cover, ignition cover, bolting the carb back up, putting the reeds back in. Took my time, made sure all the dowel pins were in place, used the new gaskets everywhere.

Final Checks

Filled it up with fresh gear oil. Put a new spark plug in. Hooked up the fuel line. You get to that point where you’ve double-checked everything, and it’s time to see if all that work paid off.

Rolled the bike outside. Turned on the gas, pulled the choke. Gave it a couple of kicks. And bam! It fired right up. Smoked a bit at first, burning off assembly oil, but then it settled into a nice, crisp idle. Sounds way healthier than before. Took it for a quick rip down the street, felt strong.

It’s always satisfying bringing one of these things back to life. Took a bit of time and skinned knuckles, but hearing it run right makes it worth it. Now, what’s the next project…